We propose a process for the fabrication of a silicon on insulator soi wafer with a silicon carbide sic insulator layer by combining plasma enhanced chemical vapor deposition and surface activated bonding without thermal stress to obtain sufficient thermal conductivity for self heating power and high frequency device applications.

Silicon on insulator wafer fabrication.

The choice of insulator depends largely on intended application with sapphire.

Silicon on insulator soi wafers are manufactured by bonding one si wafer to the other by activating the surface of both wafers and then placing them together so that a strong bond occurs first through the van der waals attraction and then by forming a covalent bond 59.

Soi based devices differ from conventional silicon built devices in that the silicon junction is above an electrical insulator typically silicon dioxide or sapphire soi technology 7.

A member of the svm sales team will determine which fabrication method is best for your project s requirements by submitting your requirements through our contact form or via email.

In semiconductor manufacturing silicon on insulator technology is fabrication of silicon semiconductor devices in a layered silicon insulator silicon substrate to reduce parasitic capacitance within the device thereby improving performance.

The basics of soi wafers.

Silicon on insulator wafers have abilities to improve many processes efficiently where other traditional si wafers are applied.

A silicon film 20 nm or thinner is epitaxially grown on sige.

Activation of the superclean si surface is the key to accomplish this bonding typically by a remote plasma process.

Soi stands for silicon on insulator wafers.

220 nm thick top silicon layer is a common choice of standard substrate for silicon photonics because at this thickness the core layer only supports one mode for each polarization at a wavelength of 1550 nm.

Silicon on nothing son consists of selective epitaxy of sacrificial sige regions in a bulk si wafer.

In a silicon on insulator soi fabrication technology transistors are encapsulated in sio2 on all sides.

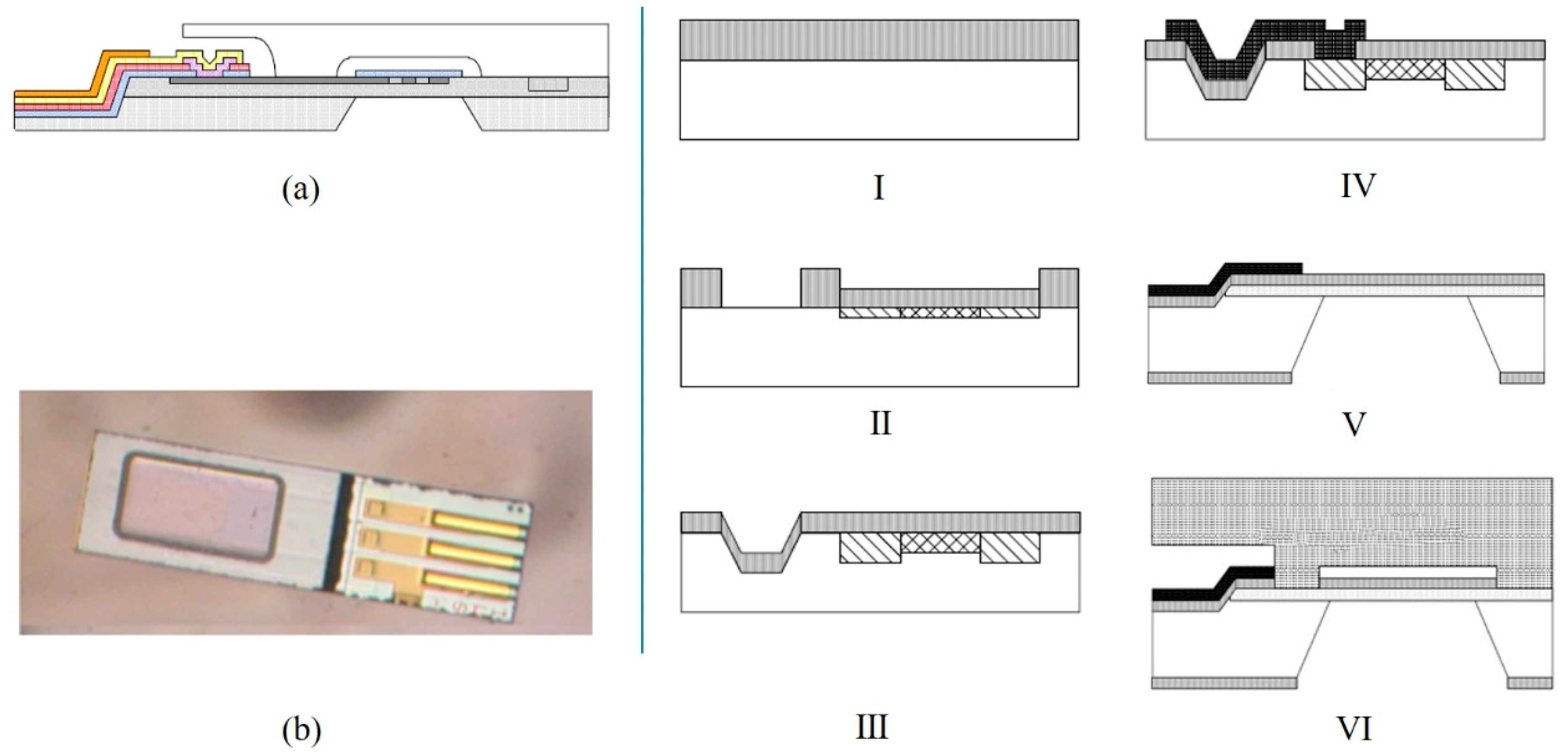

Semiconductor device fabrication is the process used to manufacture semiconductor devices typically the metal oxide semiconductor mos devices used in the integrated circuit ic chips that are present in everyday electrical and electronic devices.

An soi microchip processing speed is often 30 faster than todays complementary metal oxide semiconductor cmos based chips and power consumption is reduced 80 which makes them ideal for mobile devices.

Silicon on insulator soi is a semiconductor fabrication technique that uses pure crystal silicon and silicon oxide for integrated circuits ics and microchips.

The soi wafer has a 220 nm thick top silicon layer and 2 μm thick buried oxide layer which is consistent with our target.

Silicon on insulator fabrication process there are 3 primary ways to fabricate silicon on insulator wafers and each one produces a substrate with slightly different film properties.

Soi based devices differ from conventional silicon built devices in that the silicon junction is above an electrical insulator typically silicon dioxide or sapphire.